What is Custom Synthesis?

Home » What is Custom Synthesis?

Q1: What is Custom Synthesis and why is it important in the pharmaceutical and biotech industries?

Custom synthesis refers to the tailored production of chemical compounds according to specific requirements set by a client, typically in small to medium quantities. This process allows companies, especially in the pharmaceutical and biotech sectors, to obtain unique chemical substances that are essential for research, drug development, or other specialized applications. In the pharmaceutical industry, custom synthesis is vital because it provides access to novel compounds that can be used in preclinical studies, lead optimization, and clinical trials without the need for companies to maintain large-scale internal manufacturing facilities.

Q2: What are the key applications of custom synthesis in drug development?

Custom synthesis plays a crucial role in several stages of drug development, including:

Lead Compound Development: During early-stage drug discovery, researchers often need specialized compounds that aren’t commercially available. Custom synthesis enables the creation of these lead compounds, which can then be tested for their efficacy and safety.

Scale-Up of Active Pharmaceutical Ingredients (APIs): As a drug candidate moves through development stages, the quantity of a compound required increases. Custom synthesis ensures that the production of APIs can be scaled from milligrams to kilograms, supporting both small-scale preclinical trials and large-scale clinical trials.

Process Development: Custom synthesis services often include optimizing the synthetic route for producing a compound, ensuring cost-efficiency, scalability, and environmental sustainability.

Impurities and Metabolites: In regulatory submissions, understanding the impurities and metabolites of a drug candidate is essential. Custom synthesis allows these related substances to be created for analytical studies.

Q3: What advantages does custom synthesis offer compared to in-house chemical production?

Custom synthesis offers several advantages over in-house production, especially for pharmaceutical and biotech companies:

Access to Expertise: Custom synthesis providers often have specialized knowledge in complex synthetic chemistry, allowing them to deliver high-quality products. This expertise can be particularly valuable when synthesizing challenging or rare compounds.

Cost Efficiency: Setting up in-house synthesis capabilities can be costly and time-consuming. By outsourcing custom synthesis, companies can reduce overhead costs and focus their internal resources on core research and development activities.

Flexibility: Custom synthesis providers offer flexibility in terms of the scale and complexity of the compounds produced. This can range from producing milligram quantities for early-stage research to kilogram batches for clinical trials.

Faster Time to Market: Partnering with a custom synthesis company allows pharmaceutical firms to accelerate the drug development process by obtaining necessary compounds quickly, shortening the time required for testing and regulatory approval.

Q4: How does custom synthesis contribute to innovation in the biotech industry?

In the biotech industry, innovation often hinges on the availability of cutting-edge chemical compounds for research and development. Custom synthesis fuels innovation by providing biotech companies with access to:

- Unique chemical scaffolds for drug design, enabling the exploration of novel therapeutic mechanisms.

- Modified biomolecules, such as peptides, nucleotides, or oligonucleotides, that can be tailored for specific research applications like gene editing or targeted drug delivery.

- Specialized reagents for diagnostics, such as tagged antibodies or fluorescent markers, which are critical for developing new medical devices or diagnostics tests.

Custom synthesis services help bridge the gap between academic research and commercial biotech applications, making it easier for startups and smaller companies to bring groundbreaking therapies to the market.

Q5: What are the key factors to consider when selecting a custom synthesis provider?

When selecting a custom synthesis provider, companies should consider several factors to ensure successful collaboration:

Technical Expertise: Look for a provider with a strong background in organic synthesis, medicinal chemistry, or process chemistry, depending on the project’s needs.

Quality Standards: Ensure the provider adheres to regulatory standards like Good Manufacturing Practices (GMP) and ISO certifications, especially if the compound is intended for clinical use.

Track Record and Experience: A reliable custom synthesis partner will have a proven history of delivering high-quality compounds, ideally with experience in your specific therapeutic area.

Communication and Project Management: Clear communication is critical throughout the custom synthesis process. Choose a partner that is transparent about timelines, costs, and potential challenges.

Scalability: Depending on the project’s requirements, ensure the provider has the capability to scale production, from small-scale synthesis for early research to large-scale manufacturing for clinical or commercial use.

Q6: How does custom synthesis support regulatory compliance in the pharmaceutical industry?

Custom synthesis plays a key role in helping pharmaceutical companies meet regulatory requirements. Regulatory bodies, like the FDA or EMA, demand rigorous documentation and testing of all chemical substances used in drug development. Custom synthesis providers offer:

- Batch records and synthesis protocols that detail every step of the compound’s production, ensuring traceability and compliance with regulatory guidelines.

- Characterization of impurities and degradation products, which are essential for regulatory submissions.

- Quality control and validation services, including analytical testing, to ensure the final product meets the necessary purity and potency standards for clinical trials.

By partnering with a custom synthesis provider, pharmaceutical companies can ensure they meet stringent regulatory standards, avoiding delays or rejections during the approval process.

Q7: What are the emerging trends in custom synthesis for the pharma and biotech sectors?

Several trends are shaping the future of custom synthesis in the pharmaceutical and biotech industries:

Green Chemistry: There is growing interest in sustainable custom synthesis methods that minimize the environmental impact of chemical production. Green chemistry practices, such as reducing solvent use and adopting energy-efficient processes, are increasingly becoming part of custom synthesis services.

High-Throughput Synthesis: With advancements in automation and AI-driven chemistry, custom synthesis is moving towards high-throughput approaches. This allows for the rapid production and testing of thousands of chemical variants, speeding up the drug discovery process.

Biocatalysis: The use of enzymes as catalysts in custom synthesis is gaining traction, particularly for producing chiral molecules and other complex compounds with high specificity. Biocatalysis is often more sustainable and cost-effective than traditional chemical methods.

Personalized Medicine: Custom synthesis is playing a pivotal role in the development of personalized medicine, particularly in areas like oncology. The ability to rapidly produce tailored compounds enables pharmaceutical companies to create drugs that are customized to a patient’s genetic makeup or specific disease markers.

Process development

- We are transforming your ideas into products.

- From early discoveries and R&D chemistry in the laboratory to pilot scale for your application testing.

- Always considering economic and safety boundaries and conditions laid out for all stages of the project.

Custom manufacturing

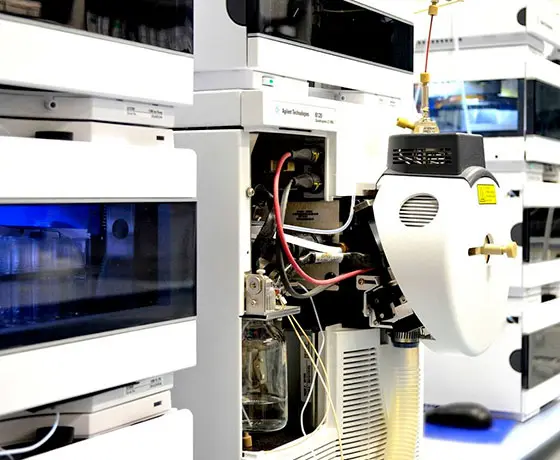

- We are running our own state-of-the-art pilot plant facility in Asia with access to a broad supplier network.

- Providing samples of your compounds and specialties in pilot scale for your extended application testing.

- Large-scale synthesis and custom manufacturing opportunities.

Analytical chemistry and purification

- Providing analytical services and quality control for your purpose.

- Several spectroscopic methods available, including NMR, FT-IR, UV/VIS, etc.

- Calorimetric methods to monitor processes at every stage of the project